Cuplock Scaffolding System

Cuplock Verticals / Standards :

Cuplock is a proven multipurpose scaffolding system that can be used in structure s for building and construction industries. It is the most versatile and optimized system of Scaffolding.

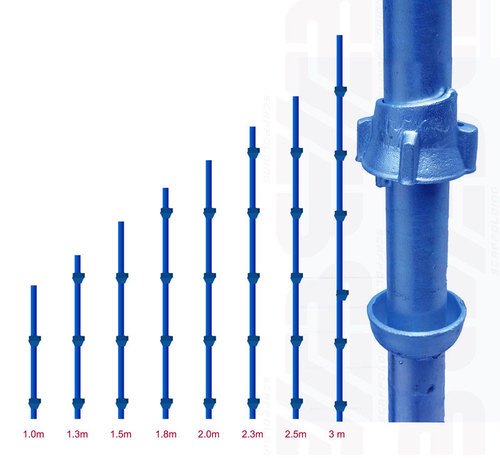

Cuplock Verticals are the principal load bearing members comprising of Sets of Top and Bottom Cups. The Bottom Cups are welded in position at 500/1000 mm distance. The Top Cups are movable and retained by a fixed stop. The Verticals are made of 40NB Medium/Heavy class pipes and are drilled for the fixing of Spigot Joints at both the ends.

Cuplock Verticals / Standards :

Cuplock Verticals / Standards :

Cuplock Ledgers / Horizontals :

Ledgers/Horizontals are made of 40 NB Light / Medium class pipes with forged Ledger blades welded at both ends. The simple robust design ensures that Led g ers / Horizontal s need no maintenance.

Length of the Ledgers / Horizontal is calculated between Centre to Centre of such two Verticals.

Sizes of Cuplock Ledgers / Horizontals :

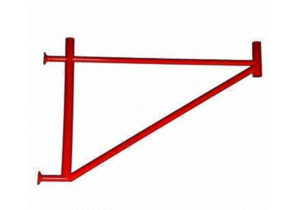

Cuplock Beam Brackets:

Beam Brackets are used to support internal down-stand beam. The use of Beam Brackets with jack accepting beam spanning from one bracket to another can avoid the need of ground based support, thus saving all the other components that would normally be needed below the drop beam. it has safe working load of 1500 kgs.

Cuplock Cantilever frames and Hop-up Brackets:

Cantilever frames are used for supporting decking or formwork at the edge of the slabs. The frames have blade ends for locating the cup joints and can accept Jacks. Such frames can have projection up to 1.5M Hop-up Brackets are a smaller version of Cantilever frames. They are generally used for awkward areas beyond the main scaffolding where scaffolds cannot be located directly adjacent to the work face.